Several questions outline the scope of any project QTS quotes for fixturing. During our initial review, we work with you to identify the critical areas and unique requirements of the requested tooling and develop a concept …

Blog

World Metrology Day 2021

If the fixtures are commissioned on the manufacturing floor and don’t produce good parts consistently and efficiently, then the return on investment (ROI) for the weld tooling is greatly reduced.

Using a Proven Process for Weld Tooling

Weld fixtures are a significant investment into the weld process – an investment that can be a tremendous asset by increasing quality, throughput, and repeatability.

Weld Fixture Validation and Run Off

If the fixtures are commissioned on the manufacturing floor and don’t produce good parts consistently and efficiently, then the return on investment (ROI) for the weld tooling is greatly reduced.

Adding Sensors to Weld Fixtures

The conversation about whether to put sensors in weld fixtures is one we are having more frequently as manufacturers continue to invest in automating weld processes.

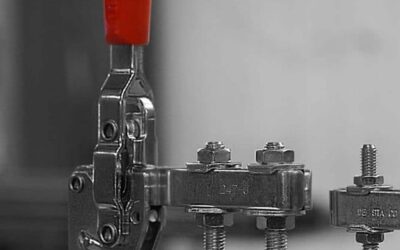

Pneumatic vs Manual Clamping

When discussing project variables and scope for weld fixture projects with customers one question always comes up – what are the cost differences and usage benefits between manual and pneumatic clamping?