Hinge Base Assemblies

Reliable. Rugged. Built for Production.

Delivered within days not weeks

Building your own fixtures but struggling to find components that perform reliably — and arrive in days, not weeks or months?

Yeah us too – so we decided to solve the problem

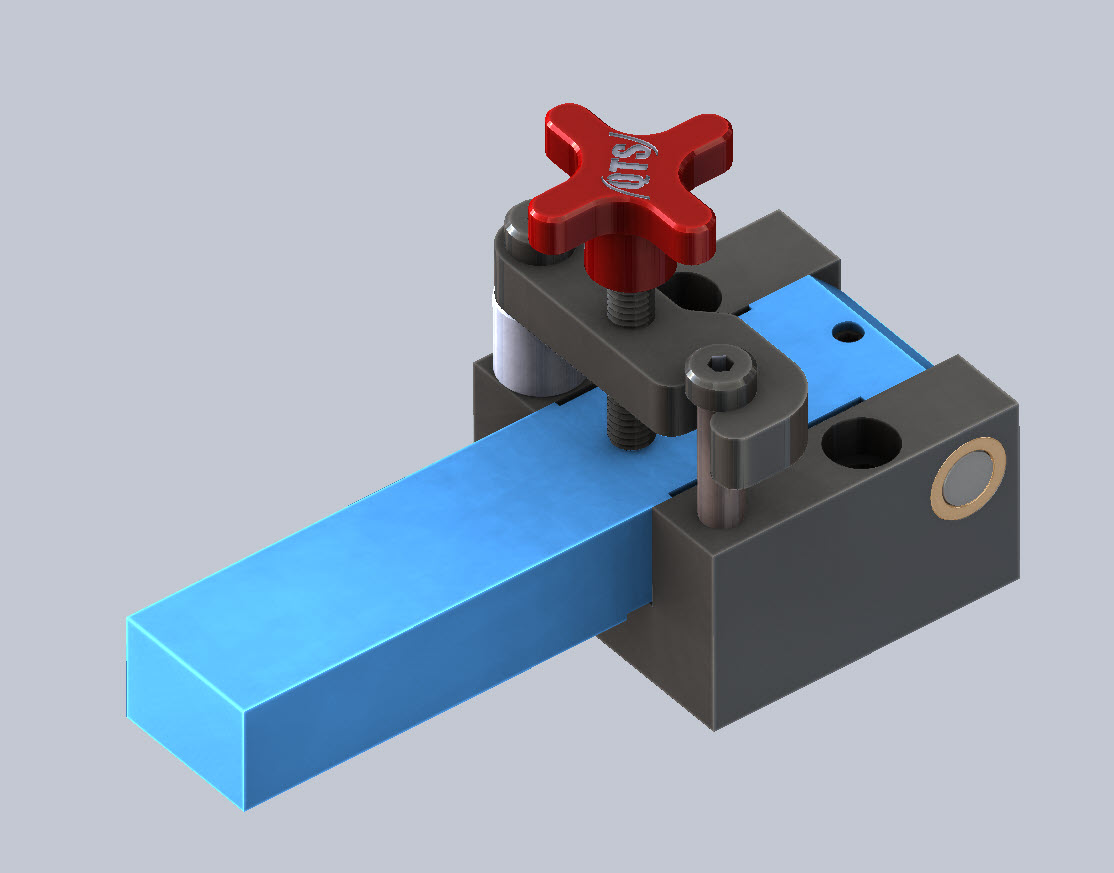

Introducing the QTS Hinge Base Assembly,

a dependable solution for high-volume production jigs.

Key Features

Designed for repeatability, ease of use, and fast changeovers.

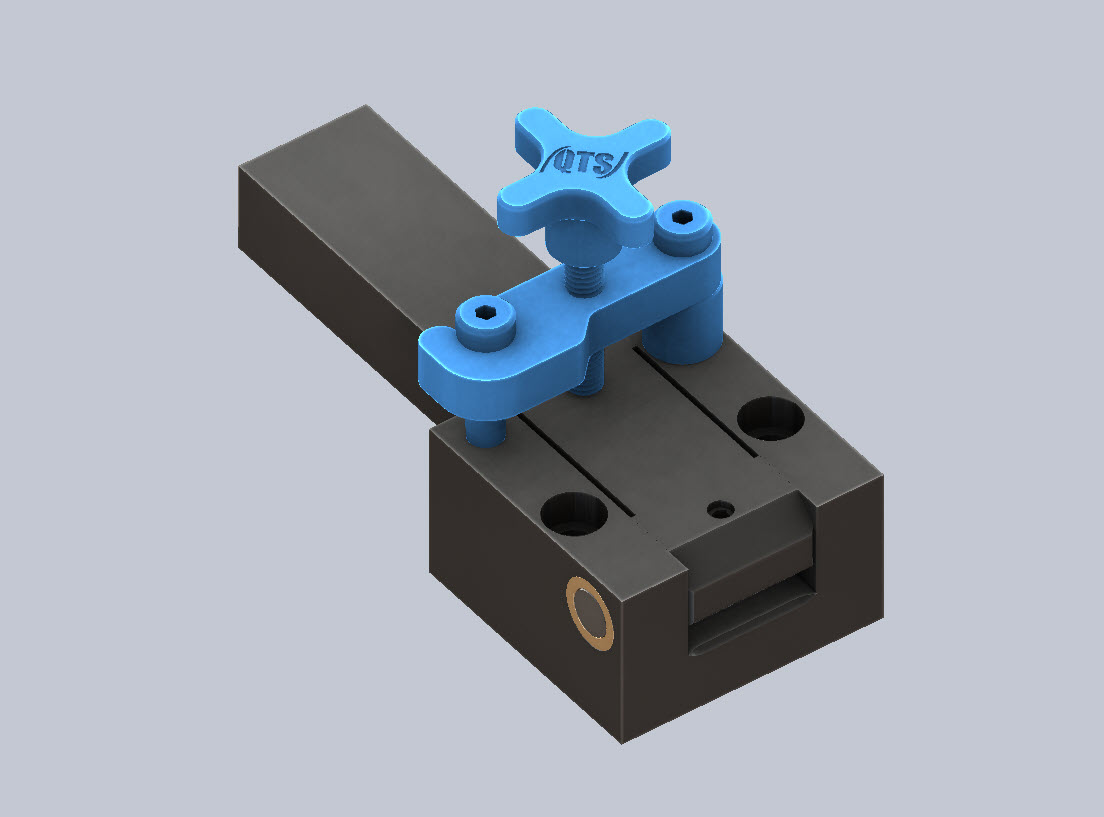

Precision Swing Arm

Precision machined arm that locates accurately and opens easily for part access.

Durable Mounting Base

Precision machined for consistent alignment and stable operation. The base includes liner bushings and setscrew for the hardened hinge pin.

Optional Swing Gate Assembly

Twist knob design holds the Swing Arm firmly closed during use for safety and precision.

Available in two sizes to suit your jig requirements.

Proudly made in the USA.

Need something custom?

We offer “blank” versions of the Mounting Base, as well as custom-machined hole patterns and arm configurations upon request. Contact us for a quote tailored to your application.

Replacement arms and components

Replacement arms and components are available individually for easy maintenance or retooling. A setscrew allows quick removal of the hinge pin for fast arm swaps with minimal downtime.

Hinge Base Assembly. Reliable. Rugged. Built for Production.

Key Features of Industrial Hinge Assembly Components

Precision Swing Arm Design

Our precision-machined hinge arms provide unrestricted part access. The machining tolerances ensure consistent alignment cycle after cycle. Operators load and unload workpieces efficiently while maintaining fixture geometry for welding, assembly, or inspection.

The swing arm design accommodates custom configurations, including specific arm lengths, mounting provisions, or alternative geometries.

Durable Hinge Plate and Mounting Base Construction

The mounting base forms the foundation of reliable fixture operation. Each hinge plate and base is precision-machined for consistent alignment and includes liner bushings that ensure smooth, repeatable motion. A setscrew secures the hardened hinge pin for quick removal during maintenance.

Standard mounting bases feature pre-drilled hole patterns. Installation doesn’t require specialized wood screws or drill bit selection—our assemblies integrate with standard fixture mounting hardware using precision-machined patterns.

Optional Swing Gate Assembly

Our optional swing gate assembly features a twist knob design that firmly locks the swing arm closed, preventing unintended movement during operations while enabling fast changeovers.

Applications for Commercial Applications

Welding Fixtures and Jigs

Welding operations demand precise part positioning throughout tack and finish welding. These heavy-duty hinges enable operators to access workpieces for tack welds, then close the swing arm to maintain exact positioning during robotic or manual welding. The precision mounting ensures repeatable part location.

The durability withstands heat, spatter, and continuous production—critical for chassis components and structural welding in commercial applications.

Inspection and Gauging Fixtures

Quality verification requires fixtures that position parts consistently for dimensional checks and CMM inspection. Our fixture hinge mounts provide repeatable positioning essential for accurate measurements while enabling quick part loading.

Precision machining ensures gage repeatability while quick-release capability streamlines workflows, protecting measurement integrity for incoming parts and finished assemblies.

Machining and Assembly Operations

CNC machining fixtures benefit from secure workholding and fast changeover capability. Operators load workpieces quickly, close the swing arm for machining, then release parts efficiently. The robust construction handles machining forces while securing solid objects throughout production.

Assembly jigs gain efficiency from hinge-based designs that position components accurately while reducing operator fatigue.

Product Information and Specifications

Understanding Industrial Hinge Types

Our product details highlight key differences between consumer and industrial hinge types. While consumer hinges, strap hinges, or gate hardware prioritize aesthetics for hardware projects, a hinge base for production jigs delivers precision-machined performance with repeatable accuracy for demanding manufacturing environments.

Available Configurations

QTS offers a hinge base for production jigs in two standard sizes for different fixture scales and load requirements. Each hinge kit includes a precision mounting base, swing arm, hardened hinge pin, liner bushings, and hardware. Machined from solid objects of high-grade steel, our assemblies deliver structural integrity for commercial applications.

Product information, including part numbers, specifications, CAD models, and an installation guide, supports your design process. For custom dimensions, we offer blank mounting bases and custom arm configurations tailored to your application.