Clamping Down On Costs

When discussing project variables and scope for weld fixture projects with customers one question always comes up – what are the cost differences and usage benefits between manual and pneumatic clamping? Of course, there are details and variables specific to each project, but there are also some universal concepts to weigh along with pros and cons to both approaches.

We recommend using a few key categories when evaluating your welding tool, and then reviewing how manual or pneumatic clamping influences each of those. Discussing these items with your engineering team or engineering services provider will help you avoid unnecessary costs and get the best value and performance for your welding fixture investment.

Weld Access

Weld access is the number one variable to consider when designing weld fixtures for either robotic or manual weld applications. It seems too basic or obvious to even mention, but inexperienced designers often overlook or fail to consider this critically important variable. When evaluating clamping methods, you need to consider how type of clamp will impact weld access.

For instance, manual clamps are mechanical, so they typically have limited stroke lengths for push/pull clamps. This can limit weld access since the clamp needs to be placed closer to the component. Conversely, pneumatic push/pull clamps can have virtually unlimited stroke, allowing the clamp to be placed further away from the component and allowing better weld access. However, the longer the clamp stroke the longer the clamp body, which can cause space and access issues due to the clamp body getting in the way of welding.

Ergonomics

Worker ergonomics is playing an increasing role in fixture design and will continue to be a focus for designs into the future. Attracting and retaining good welders is a huge issue and companies are doing all they can to accommodate and retain their welders. If your weld fixtures and tooling are easier to load, clamp, unload, and unclamp, your welders will not only be more productive, but will be happier, healthier and safer in their everyday work environment and have a higher likelihood of sticking around.

Clamping can play a large role in the ergonomics of the weld fixture in several areas. One is actuating the clamping. Manually clamping and unclamping parts can be physically demanding and can cause long-term injuries, while pneumatic clamping provides better worker ergonomics. Also, depending on the size of the weldment and fixture, large weld fixtures that require manual actuation can present ergonomic and safety issues.

Safety

Safety is a major ongoing concern in manufacturing environments and clamping decisions can be a factor for increased safety.

One major safety benefit of pneumatic clamping is the added control you can incorporate into the weld tooling. For instance, if you are rotating the fixture at all for weld access or to weld the backside of an assembly in either a manual positioner or a robot, you can incorporate controls that will not allow the fixture to unclamp unless the fixture is rotated into the “home” position. It sounds simple, but an operator rotating a fixture with the parts unclamped and causing parts to fall out with potential for serious injury happens all the time.

When incorporating pneumatic clamping safety needs to be top of mind as well. Utilizing safety features like two hand anti-tie down controls, flow controls, guarding, and sequenced plumbing is critical to safety when using pneumatic clamping. It is usually best to consult a professional, like any of our engineering staff, if you aren’t experienced in the safety portion of pneumatics or have questions about how to promote safety in your clamped fixtures.

Time Savings

Cycle times are critical in manufacturing and are often the primary driving factor for justifying the investment into new or improved weld tooling. When looking at the time savings factor of the manual vs. pneumatic equation, the first thing to consider is the overall cycle time of the weld process. If you are welding manually with one operator, the faster the load and weld time, the faster the overall production. However, if you have other constraints in the weld process, like multiple operators loading the fixture, or a robotic weld cell, then you need to make sure to consider those variables as well when weighing time savings.

For instance, if you are robotically welding with an “A” side and a “B” side, then your load/unload times should be balanced with the opposite side welding cycle time. In other words, if side “A” has a 6-minute weld cycle, there is not much cost benefit to investing additional money into a fixture just so you can decrease the load/unload time to under 6 minutes. However, if your weld cycle time on side “A” is 6 minutes, but it takes 12 minutes to load/unload side “B”, you are decreasing your throughput on side “A” in half by your load/unload times. In this case, there would more than likely be a cost justification to investing in pneumatic clamping or other time saving features, like pneumatic part ejection, to decrease load/unload times,

Another tool for evaluating time savings in pneumatic vs. manual clamping is how many clamps are needed in the weld fixture. With manual clamping you actuate the clamps manually to clamp and unclamp (obviously), so the more clamps you have the more time it takes in order to actuate all of them. With pneumatic clamping, you can plumb controls to clamp or unclamp with the push of a button, potentially saving a lot of time in your load/unload cycle.

Durability

The variables and cost benefits of fixture durability go beyond manual or pneumatic clamping, however. Tare durability factors to consider when deciding on not only the clamping method, but specific brands and types of clamps.

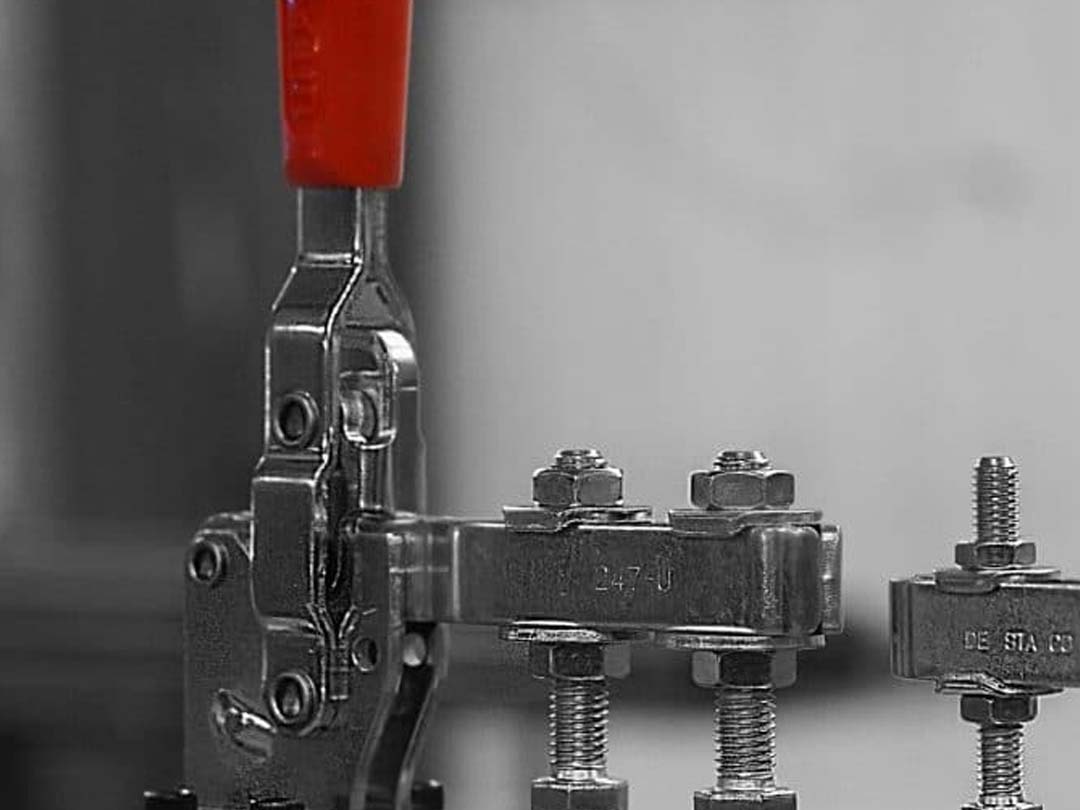

With manual clamping everything is mechanical motion, so there tends to be more moving parts and therefore decreased overall durability. That being said, more of a factor in durability is the type of manual clamp used. For instance, clamps constructed with stampings will wear far more quickly than clamps constructed with forged components.

With pneumatic clamping, lower quality clamps with exposed rods and those constructed with stampings will be less durable than fully enclosed automotive grade clamps.

The bottom line on clamping durability is understanding the method of clamping does not play as much of a role as the quality of clamp used. A lot of the time estimated annual usage (EAU) plays a major role when determining the clamp construction and durability. You don’t want to use a low-budget clamp to weld twenty thousand parts per year, but you don’t necessarily want to use fully enclosed automotive grade clamps to weld three hundred parts per year either.

While this isn’t an exhaustive list of things to consider when determining what clamping to utilize in your weld fixture construction, it’s an excellent place to start. Every application has unique challenges and variables to consider, so there is certainly no “one size fits all” solution when it comes to clamping or designing and building weld tooling for that matter. Our designers and project managers here at Quality Tool Service work with customers every day to help them find the best solutions for their weld fixture applications in industries ranging from agriculture to consumer goods to manufacturing.

We design, build, and commission hundreds of weld fixtures every year and would welcome the opportunity to help you with your next weld tooling project! Contact us today to discuss!